The Hong Kong-listed company aims to complete by the middle of next year the first phase of a 500 megawatt (MW) plant in Kunshan, an eastern city in Jiangsu province near Shanghai, for solar modules that integrate cells packed with perovskite and crystalline silicon. , said Fan Bin, chairman of GCL Perovskite.

“The value of [nascent] “perovskite technology is in a good place to increase its efficiency in energy conversion,” he said. “That’s why manufacturers are willing to invest in its development.” perovskite-silicon technology can be lower than crystalline silicon technology, he added.

The plant in Suzhou, Jiangsu will spend 500 million yuan to purchase equipment and 200 million yuan to assemble a factory with dust-free clean rooms. A second line of the same power will be added later.

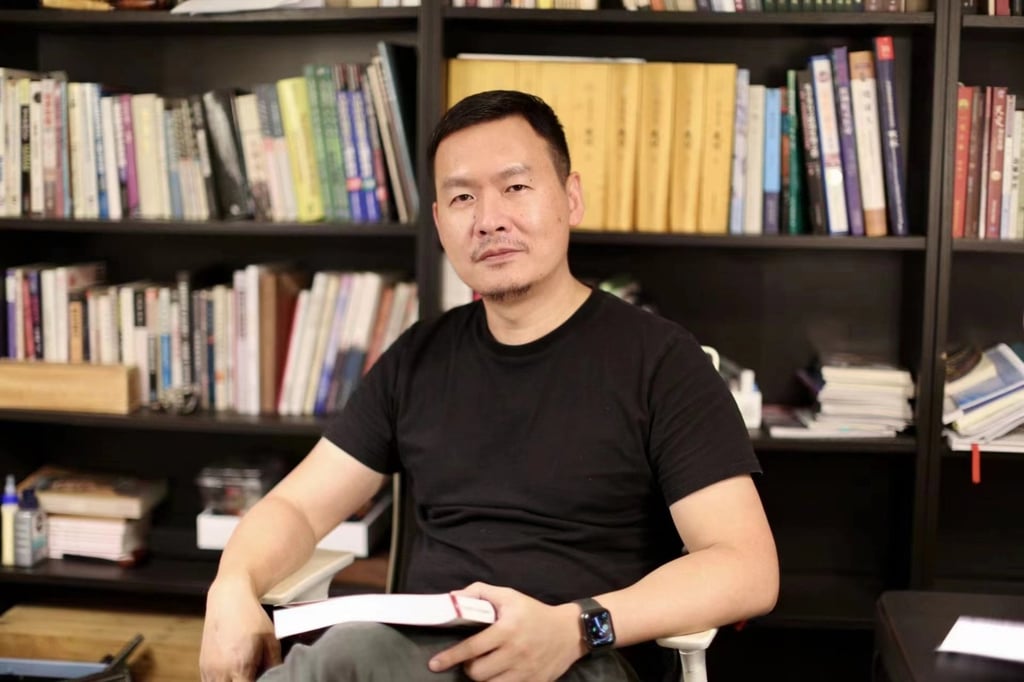

Fan founded the company in 2013 to sell the technology. GCL Tech bought more than 40 percent of the firm in 2017, giving it a controlling stake.

GCL’s perovskite-silicon product has passed functional stability tests by certification provider TUV Rheinland, based on the same parameters as crystalline silicon products, he said. It may take two to three years for consumers to trust new technology, he added.

Fan said the main reason for that is because conventional crystal technology has only slightly improved the efficiency of converting sunlight into electricity by 0.1 percent annually on average from 2017 to 27.3 percent now.

The upper limit of conversion efficiency for silicon solar cells is 29.4 percent, versus 43 percent for the new perovskite-crystalline silicon technology, according to the Xian-based manufacturer of wafers and modules. Longi Green Energy Technology.

GCL and Longi are among more than 30 firms in China, South Korea, Germany and Japan working to commercialize the technology, according to Charles Yeung Man-chung, chief financial officer at GCL Technology.

Perovskite, when used as a solar material in the form of a hybrid organic-inorganic lead or tin halide-based chemical compound, is much better at absorbing sunlight than crystalline silicon, but can degrade under extreme temperatures and humidity.

GCL, which has built a 100MW pilot production line by 2021, achieved an efficiency of 26.3 percent for perovskite-silicon modules, which is higher than the 22 to 23 percent for most commercial products. crystalline silicon, Fan said.

Daiwa Capital Markets analyst Leo Lu said the biggest challenge facing early adopters of perovskite technology is its poor stability, with a lifespan of only about 10,000 hours now.

“The perovskite-silicon tandem solar cell business is not feasible within the next three years according to other major solar cell companies,” he said. It remains a promising technology in the long term, Lu said, adding that it will help the industry eliminate oversupply as the entire supply chain will have to be rebuilt.

Jessica Jin, lead research analyst on clean technology and renewables at S&P Global Commodity Insights, said most perovskite materials are relatively cheap to produce and require expensive manufacturing facilities. down for working.

He said that the perovskite-silicon tandem technology is unlikely to be fully developed in the next five years. The industry, which is targeting 33 percent efficiency by 2030, will take time to improve stability, stability and sustainability, he added.

#Chinese #solar #firm #betting #million #pioneering #technology #boost #sector